Working principle of different filling machines

- Automatic filling machines can use a number of different filling principles to get the product into the bottle. Each filling principle has its own unique benefits or advantages. While more than one type of liquid filler may work for a given project, each project will ultimately have an ideal filling machine, or filling principle, for the job to be completed.

- Overflow Filling Machine

- The principle behind the overflow filling machine is the ability to fill to a specific level on each and every bottle, even if small discrepancies exist in individual bottles. This filling machine offers obvious aesthetic value to products that are packaged in clear containers, such as bottled water and window cleaners. As with all of the filling machines discussed in this article, overflow fillers can be manufactured to meet almost any production demand, as tabletop, semi-automatic or fully automatic bottle fillers.

- The overflow filler will almost always be the ideal filling machine for products that are packaged in clear containers. However, the machine will be limited by the viscosity of the product. Overflow fillers work well with thin to medium viscosity products and even products that foam. Special nozzles allow the overflow filler to fill each and every bottle to the same level, regardless of slight differences in the interior volume of the container. For products in clear containers, a level, consistent fill leads to good shelf appeal, adding aesthetic value to the filling process.

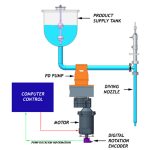

- Gravity Filling Machine

- Gravity filling machines allow for the simple filling of free-flowing products using a tank positioned above the fill heads and a time based volume fill. Gravity filling machines can use a number of different filling nozzles and can include options such as diving heads, foam control and other extras to hand tailor the machine to the individual project.

- Gravity filling machines are ideal for free-flowing products that require a simple timed fill. These machines can use a variety of different filling nozzles based on the product and the container being filled. Unlike the overflow filler, gravity filling machines do not use a re-supply, or re-circulation, system and do not require specialized nozzles. For these reasons, the gravity filler offers an economical solution for lower viscosity, free-flowing products.

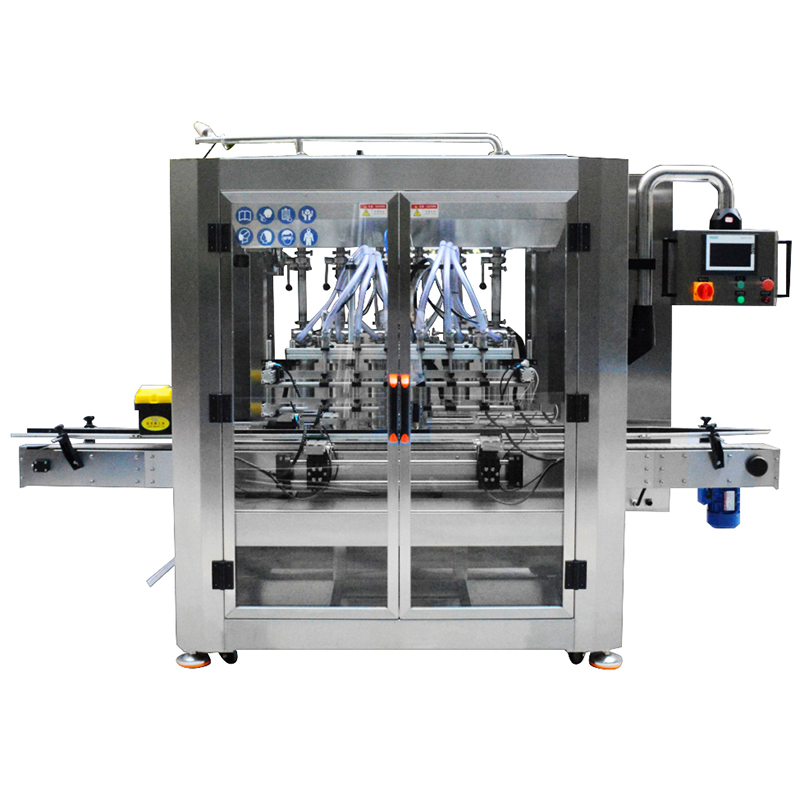

- Piston Filling Machine

- Piston filling machines also use a volumetric fill principle, but allow for thicker products to be filled such as pastes, jams and jellies. Generally speaking, the piston will pull back to the set point during each fill cycle, allowing the same amount of product into the cylinder with each stroke. As the piston reenters the cylinder, the product is pushed out through a nozzle or nozzles to a waiting container.

- Because the volume of the cylinder on the piston filler will not change, this liquid filler provides a highly accurate volumetric fill. While able to handle particulates like the pump fillers, the piston filler can also work with larger chunks in products, such as tomato paste or jams and jellies with fruit chunks.

- Pump Filling Machine

- Pump filling machines offer the versatility to handle not just thin products, but also higher viscosity products as well. The pumps used on these liquid fillers will be matched to the project on a case-by-case basis, allowing the packaging machine to be manufactured with the pump that best suits each individual project. Pump fillers can also handle products with particulates such as salad dressings or soaps with grit. A variety of nozzles can also be used on the pump filler to match the specific application for which the machine is built.

- Machines using a pump filling principle can also be ideal for thicker, more viscous products. The type of pump used will depend on the product and fill being completed, with many options available. For example, a gear pump may be used to move product based either on time or on the turn of the gear (pulse based). A peristaltic pump uses rollers that allow the product to be pumped without coming into contact with pump components, only the tubing, which makes this pump ideal for pharmaceutical and some food or flavor processes.

- Choosing the correct filling equipment can have a measurable effect on the efficiency and productivity of a packaging line, and ultimately the bottom line for any packager. For more information on any of the different filling principles or which will work best for any given project, contact VKPAK today.

Previous Post

Previous Post Next Post

Next Post